PLM for Industrial Automation

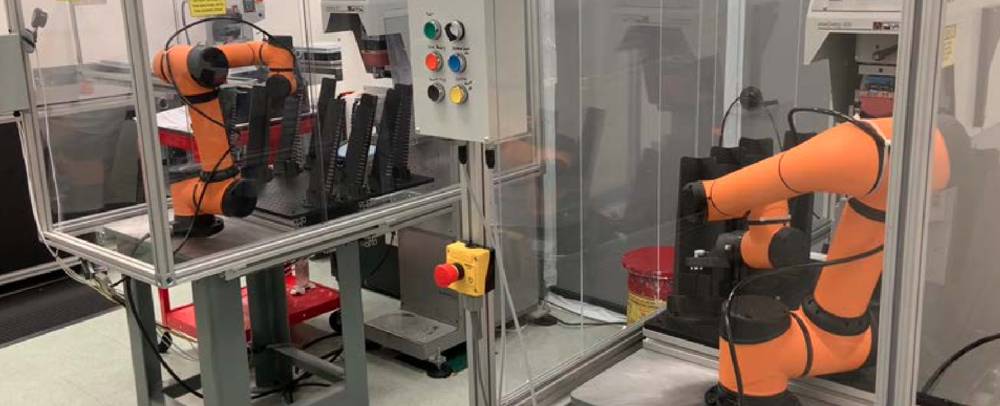

Industrial Automation startups are disrupting traditional industries with new value propositions and affordability. From modular, mobile, pick and place robots to Additive Manufacturing (AM) machines, Industry 4.0 is being driven from the bottoms-up, not the top-down. Duro is part of that movement.

Industry 4.0, originally a high-tech strategy initiative from the German government, is gaining momentum globally, not due to government leadership but by the economic advantages of affordable emerging technologies which are disrupting traditional engineering best practices. The confluence of SaaS solutions, global supply-chain-centric product designs, distributed workforce, and availability of commodity modules/components, has accelerated the Industry 4.0 movement. Commercial startups, often beginning as SPAC’s (Special Purpose Acquisition Companies), take full advantage of SaaS engineering solutions to conceive, design, simulate, build, and maintain groundbreaking new products. Cross-functional collaboration is essential because engineering processes lack structure and involve many roles; mechanical, electronic, software, and IoT as examples. Enter Duro, the next-generation Cloud-Native PLM solution to aid engineering collaboration with industrial automation software.

What Duro delivers for Industrial Automation companies

-

Affordability

Duro’s Cloud-Native platform for industrial automation engineering may be enabled in hours, not weeks or months because the approach does not require redefining business processes or customization. As a native SaaS application, it is both flexible and scalable for automation product development; customers pay only for what they use, no hidden surprises, no hardware or heavy consulting costs.

-

Traceability

Industrial Automation products share common core components like servo motors, IoT devices, and hydraulic motors. Duro’s structured workflows, event logs, parametric search, history tables, and roll-back capability ensure traceability of who did what, how, and why.

-

Interoperability

Duro has commonly needed deep integrations to mCAD/eCAD, ERP, e-catalogs and desktop Office, all Out-of-the-Box which ensures an uninterrupted Digital Thread. A RESTful API allows users to configure other integrations. Event triggers using webhooks send notifications to adjacent systems, thus automating the Digital Thread.

-

Agile Team Collaboration

Industrial Automation engineering products have a high percentage of procured content sourced from suppliers. This means that all product stakeholders, including suppliers and customers, must collaborate to make decisions fast. Duro’s Git Workflow paradigm used in the automation engineering software industry, where structured workflows are uncommon, suits industrial automation product development perfectly.

-

PLM Enterprise

Product development technology for companies that require a custom PLM deployment.

-

PLM Professional

Product development software for teams that need to roll out an easy-to-use PLM that just works--right out of the box!

-

PLM Starter

PLM technology for teams that need a simple, intuitive, and cloud-based single source of truth.