The Business Benefits of Cloud-Native PLM

Updated April, 2024.

James White, VP of Strategy, Duro

PLM (product lifecycle management) is usually associated with improving engineering efficiency but is rarely associated with successful business outcomes, such as profitability or sales performance.

However, cloud PLM software should be seen as a strategic business imperative that elevates engineering from a cost center to an innovation center to facilitate commercial success.

This blog connects the dots to reveal how cloud-native PLMs can drive successful business outcomes directly.

Lost engineering productivity can result in higher product costs and missed deadlines

According to a study by leading PLM analyst firm Tech-Clarity, 96% of manufacturers report that lost engineering productivity negatively impacts their businesses.

The results of the study, shown below, reveal that wasted engineering time can result in higher product costs, missed deadlines, and challenges staying on budget.

Coupled with modern products’ complexity and supply-chain centricity, manufacturers face challenges in improving engineering efficiency.

Inefficient engineering processes can lead to challenges with sales and profitability

PLM software ensures that engineering processes are efficient, repeatable, and flexible by providing workflows and best practices.

Here are two examples of end-to-end process failures that could be improved by implementing Cloud PLM and focusing on improving engineering efficiencies:

- “We lost the deal because we couldn’t get a quote out on time.”

- “We won the deal, but we are losing money on each product we sell.”

In the first example, sales might be blamed for not sending a quote in time. In the second, procurement or finance might be held accountable for product profitability issues.

However, as explained below, engineering plays a critical role in both scenarios.

1 – Couldn’t get a quote on time

The quote might be delayed if sales use manual, paper-based processes to find part information for a custom product. In a competitive bid process, sending the customer a quote requires urgency, and sales may need more time to get updated pricing.

This could be resolved with more effective communications and data sharing between sales and engineering systems, specifically by using PLM as the hub to connect product data with financial systems.

2 – Losing money on each product

With profitability issues and time crunches, sales may have to cut corners when issuing contracts by using older product proposals to estimate new ones. Small changes, such as a different cooling fan or circuit board, might cost more than usual due to supply chain shortages.

Live sourcing data, viewed in Cloud PLM, can enable engineers and procurement teams to see how minor changes impact the product price. With access to up-to-date lead times and pricing information, engineers could quickly alter a design to factor in the total cost and make informed design decisions.

PLM software provides a centralized data repository with access to design, sourcing, and change documents. It should be part of strategic business initiatives, and it should be used to enable business outcomes from engineering to production and sales.

Connecting Cloud PLM to business outcomes

The best way to make PLM a business imperative is to highlight how efficient engineering processes directly contribute to positive business outcomes.

So, how does a tool designed for engineers help drive improvements throughout the business?

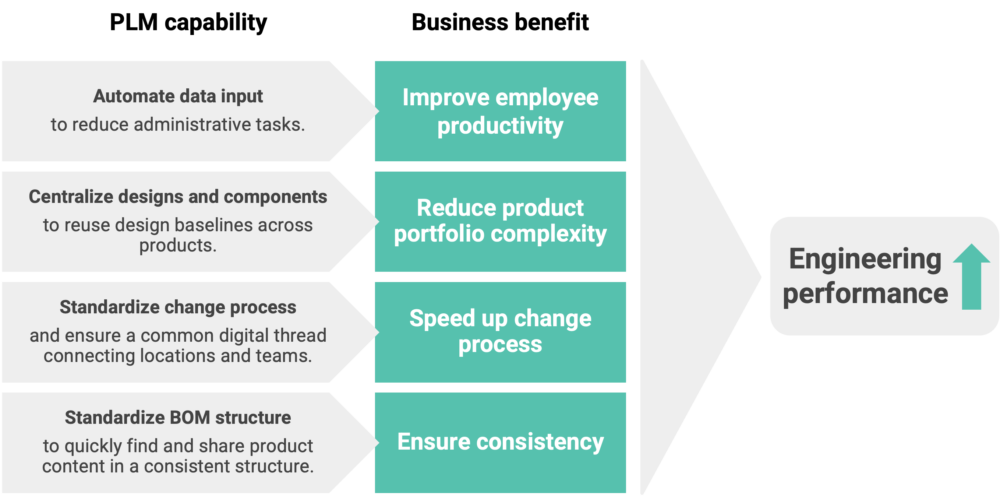

Engineering performance

More streamlined processes enable engineers to create more innovative products because they have time to experiment and evolve designs faster. Often, engineers choose the first thing that works rather than the best design because they are under time pressure.

Wasting time on administrative tasks, finding documents, and inputting data impacts their time to iterate and design for profitability and performance.

Cloud PLM ensures all stakeholders have access to the correct information and reduces much of that manual admin time through automated data input and standardized processes.

By centralizing and standardizing BOM structure, change process, and component information, engineers have more time to focus on designing products.

Maintaining consistency enables the business to scale because more products can be designed with the same human resources.

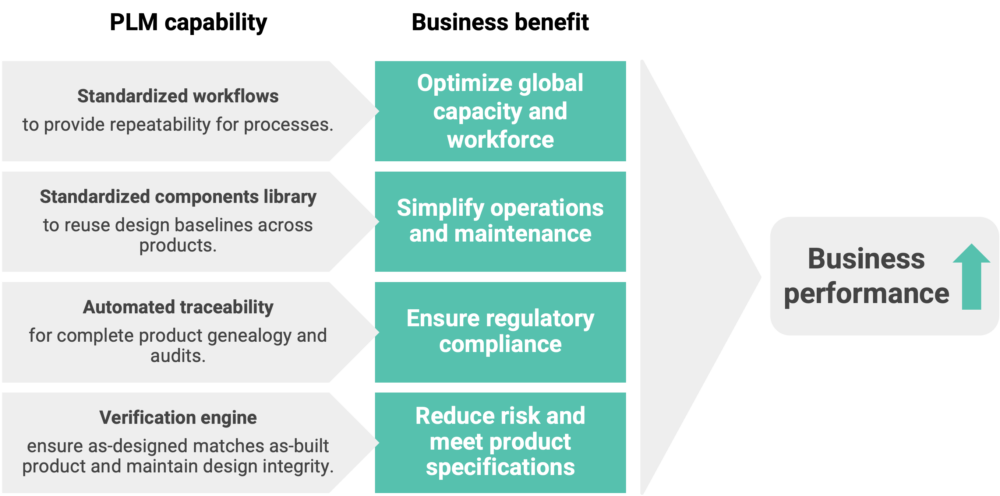

PLM Capability v Business Benefits

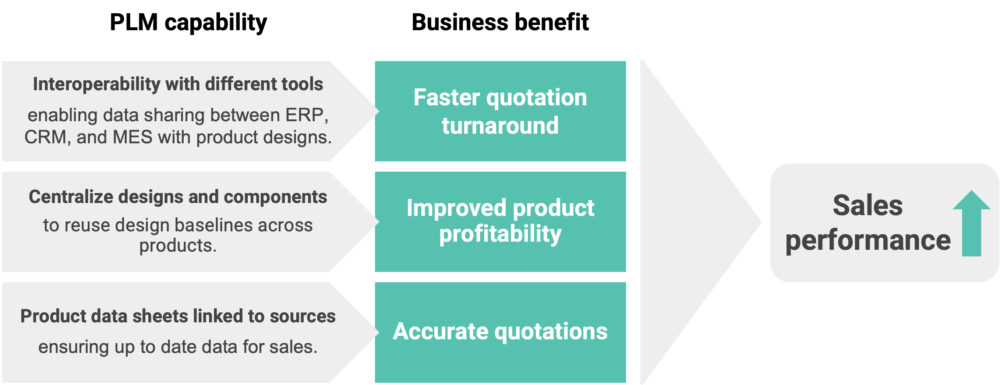

Sales performance

Sales need fast access to accurate information so that they can respond to customer quotes for non-standard products. When products require customization, such as adding an international connector or customizing a product for a unique installation, sales must get revised costing information from engineering, manufacturing, and finance to build an accurate proposal.

It could be a lengthy process for sales to call each department or wait for email replies with the calculated pricing. Cloud-native PLM can be used as a backbone for product design and can be connected digitally to ERP, MES, and other enterprise systems involved in the quoting process. This solves the problem of calculating costs using financial and time data from numerous systems or databases.

Cloud PLM facilitates the transfer of engineering BOMs into ERP for costing and work planning. The schedule and work effort, including labor rates, machinery, and materials costs, are then calculated in the ERP.

Finally, this information can be transferred into a financial system to calculate the correct price and margins before digitally approving the quotation and releasing it to sales to present to their customer.

PLM capabilities + Business benefits + improved sales performance

Business performance

Business performance is an indicator of the health of the business. PLM helps link teams and tools, ensuring that everyone follows the proper process to encapsulate corporate governance standards. Standard workflows ensure repeatability across all departments, enterprises, and physical locations so that teams work efficiently and to their maximum capacity.

By sharing product content among departments, it’s easier to distribute products and inventory and work as a single virtual organization regardless of physical location. Finally, PLM provides traceability of the entire product design history.

By managing a digital paper trail of the product’s complete genealogy, manufacturers and engineers can compare as-designed to as-built products to ensure accuracy, meet specifications, and reduce risk.

PLM capabilities + Business benefits + improved business performance

Elevating Cloud PLM to Business Imperative Status

Cloud-native PLM, complemented by adjacent cloud-native solutions, gives much-needed flexibility, scalability, and affordability for all tiers of manufacturers. It enables more efficient engineering processes, which benefit the overall business.

Engineers can more easily share product and supply chain data throughout the business by connecting cloud-native PLM to other cloud-native solutions such as ERP, CAD, or MES.

Extending PLM beyond engineering into adjacent business functions such as operations, procurement, finance and sales, PLM becomes a business imperative.