How integrating PLM with Solidworks enhances hardware development

As companies strive to bring new hardware products to market quickly and efficiently, integrating product lifecycle management (PLM) and computer-aided design (CAD) becomes increasingly important. One such integration is between Duro’s PLM platform and SolidWorks, a popular CAD tool.

By syncing design, and bill of materials (BOM) data from SolidWorks to Duro, your engineers can achieve data continuity and quickly disseminate product data to the larger organization.

In this article, we will explore how Duro and SolidWorks work together, and detail the key benefits of using the Duro add-in for SolidWorks.

Understanding how Duro and SolidWorks integrate

SolidWorks is a popular solid modeling CAD and CAE (computer-aided engineering) software used primarily for the development of mechatronic systems from beginning to end. Integrating PLM and CAD provides an easy way for your teams to utilize a PLM-based part numbering system.

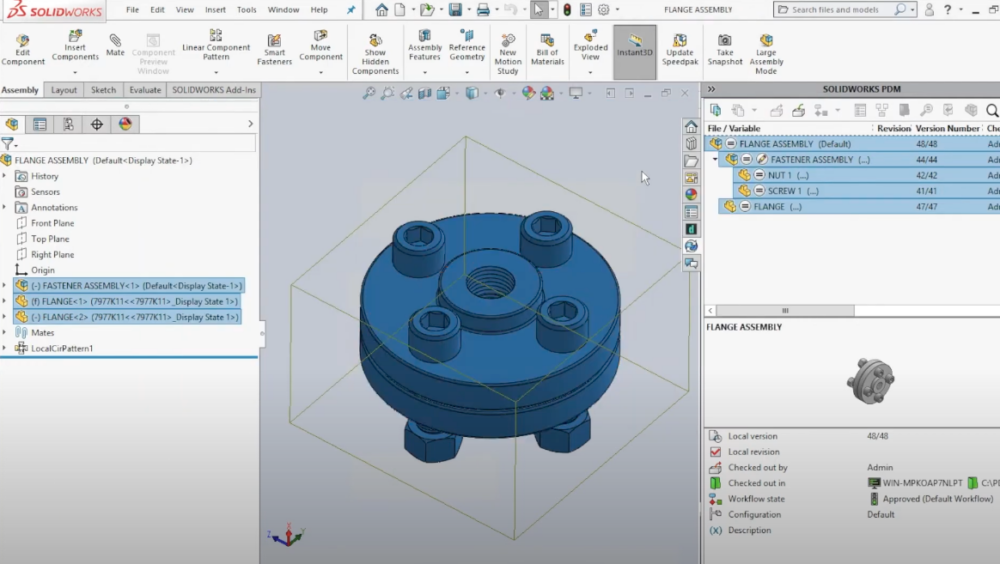

The Duro add-in for SolidWorks bridges the two platforms, enabling your mechanical engineers to map BOMs and product data to Duro without manual data entry. Your teams can rapidly sync and release new design revisions from SolidWorks to Duro, achieving an easily-referenceable source of truth for the entire organization.

Key benefits of using the Duro add-in for SolidWorks

The key benefits of using the Duro add-in for SolidWorks include achieving BOM and data continuity between the two platforms. Duro PLM provides a central location for storing BOMs and product data.

But the benefits don’t stop there. Below, we’ll explore four of the most significant advantages of using the Duro add-in for SolidWorks.

Achieves BOM and data continuity between SolidWorks and PLM

The Duro add-in provides a user-friendly and efficient way to synchronize and release new design revisions from SolidWorks to Duro. It automatically maps your SolidWorks CAD BOM structure into Duro. This helps maintain data accuracy and reduce errors while enabling your teams to work more collaboratively and efficiently.

By using Duro as a central location for BOMs and product data, your organization can achieve an easily-referenceable source of truth for your entire enterprise. Teams can confidently make decisions based on accurate and up-to-date product information and avoid costly errors and delays from working with outdated or incorrect data. Duro’s ability to connect with other systems, such as ERP, makes it a powerful tool for achieving data continuity and sharing information between design engineers, operations and supply chain teams.

The Duro add-in for SolidWorks provides a valuable solution for organizations seeking unity between their design and PLM platforms. You can achieve greater visibility and control over your product lifecycle while enabling better decision-making across the enterprise.

Standardizes your part numbering

A PLM-based part numbering system allows you to standardize and centralize part numbering and avoid costly downstream issues in manufacturing.

Part numbering systems are not all created alike, and Duro’s solution is based on industry best practices. Duro’s SolidWorks add-in enables you to easily assign part numbers to parts and assemblies using a category-driven scheme. This system results in efficient and accurate management of parts and assemblies and streamlines the product design process by automating publishing and reducing manual data entry.

While a CAD-based part numbering system is a great way to get started, it can introduce several downstream risks. For example, when multiple CAD tools are used throughout the organization there will be different standards across each application.

Uniquely identifying each component within its originating CAD tool becomes a burden as components are merged into a common BOM from multiple CAD sources. A PLM tool provides both a means of connecting content from disparate engineering design sources and managing a part numbering system that can, in many cases, be pulled back into each CAD tool.

Adopting a PLM-based part numbering system is recommended before the product development lifecycle moves into the design stage. This helps avoid conflicts with external part numbers, so you can navigate multiple BOMs from different applications or teams.

Duro offers a PLM-based part numbering system that incorporates standards for naming, and revision data. It ensure data continuity across multiple CAD tools, and any downstream applications connected to Duro, such as an ERP system.

Reduces manual data entry

Automating the publishing process and reducing manual data entry is critical to any efficient PLM workflow. The manual entry of product data is prone to errors, such as input mistakes, data redundancy, and data omission. By automating this process, companies can reduce the likelihood of errors and speed up product development.

With Duro’s add-in for SolidWorks, your designers and engineers can automatically release new revisions and publish released files in different formats (e.g., PDF, STEP, Parasolid, etc.) to Duro without manual data entry. This helps ensure that the most up-to-date product data is readily available to everyone involved in the product design process, from engineering to supply chain to manufacturing.

Furthermore, with Duro’s automation capabilities, designers and engineers can eliminate time-consuming manual tasks associated with managing product data, freeing them up to focus on more critical design tasks. This increases efficiency and productivity, ensuring the product design process is completed promptly and cost-effectively.

By reducing manual data entry, Duro’s add-in for SolidWorks enables your teams to work in quicker cycles, helping to make informed decisions based on the most current product information. This results in better collaboration among team members, fewer errors, and reduced design cycle times. In turn, your company can improve time to market, reduce development costs, and boost profitability.

Synchronizes attributes

Duro’s attribute synchronization with SolidWorks is not only efficient, but highly customizable. The add-in allows users to map attributes from SolidWorks to Duro and configure the synchronization process according to their needs. Your organization can customize the data management process across the two systems, tailoring it to meet your unique requirements. With the ability to configure the synchronization process, organizations can ensure that their critical data is captured accurately and consistently across systems.

Another advantage of Duro’s attribute synchronization with SolidWorks is that it enables easier identification and resolution of data discrepancies. With a centralized platform for data management, you can quickly identify and resolve differences between systems, such as SolidWorks and an ERP like NetSuite. This ensures that you maintain accurate product information and that data discrepancies do not lead to costly errors or delays.

Step-by-step guide for syncing design data to Duro from SolidWorks CAD

You can follow a simple step-by-step guide to sync design data from SolidWorks CAD to Duro. Your SolidWorks design data will be automatically synced to Duro, making sharing accurate design data with your organization fast and easy. Sign in to the SolidWorks Duro add-in with your Duro credentials.

- Select the desired components you want to synchronize using the checkbox to the left of the component title in the Duro Add-in (right task pane in SolidWorks window).

- Click on #PullPartNumber.

- Select the appropriate category for each component from the dropdown menu

- Your data will automatically sync to Duro. You can view the synced components and assemblies in your Duro account. Updates to metadata for synced components can now be sent back and forth between SolidWorks and Duro. Additionally, the latest revisions of all synced components can be released from SolidWorks to Duro.

Streamline BOM management and part numbering with Duro’s SolidWorks add-in

Duro’s SolidWorks add-in provides a powerful solution for streamlining BOM management and change management processes. It allows easy integration and data transfer between CAD and PLM systems.

With Duro’s add-in, companies can achieve connected design and engineering processes, improve communication and collaboration, and maintain data continuity across all systems.

To learn more about how Duro’s SolidWorks add-in can benefit your company, visit our SolidWorks add-in for Duro page.