How a part numbering system saves you time and reduces duplication across systems

Part numbering systems, as mundane as it may seem, can be a controversial part of how a hardware manufacturing company manages its design, production, and inventory. Getting it right early reduces duplication and makes part numbers easily recognizable and searchable. A cloud-native Product Lifecycle Management (PLM) tool can be used to make sure you use best practices.

Part numbering schemes range from random numbers that simply increment with each new part, to highly intelligent numbering schemes that provide information in each set of digits within the part number. Implementing part number scheme best practices save companies time and effort throughout the design, production, buying, warehousing, and delivery processes.

Done properly, part numbering schemes can make companies efficient and agile. The Duro cloud-native PLM system includes part numbering best practices so that companies don’t need to invest time in implementing their own intelligent numbering conventions. In fact, approximately two-thirds of Duro’s customers use its parts numbering system, which easily integrates with both CAD and in-house ERP systems.

Schedule a demo to learn more about Duro’s part numbering system.

Simple Part Numbering Schemes: Not So Simple

Before discussing how to create a part numbering scheme, it’s worth noting that many companies simply avoid thinking about assigning part numbers and just leave that to the person who first orders or notes the parts. Often, companies will simply maintain a spreadsheet that is updated every time someone adds another part to the system, simply adding an increment to the previous part number.

Another, more complex part numbering convention, is to use a system where each set of digits represents specific characteristics of the part. For example, the first digits represent the type of part, the second set of digits represent the country of origin, etc. These category schemes are excellent, but they require centralized management and are tailored to a specific organization.

While assigning the numbers in this system is simple, there are several drawbacks:

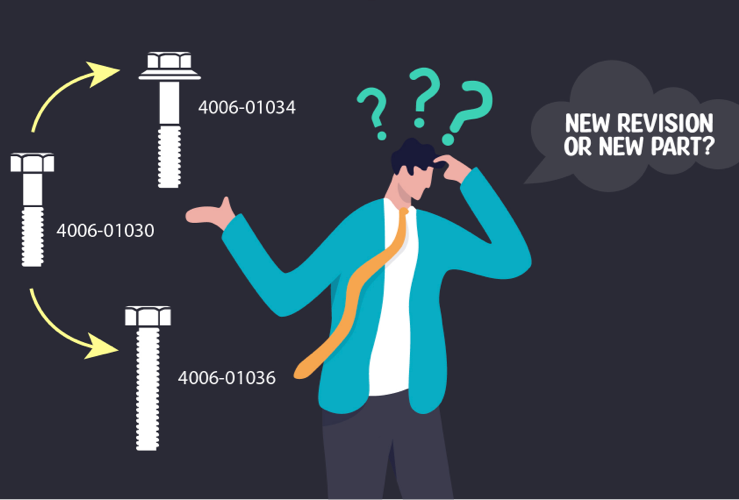

- After the part number is assigned, calling up or remembering the part number is difficult because it has no logic

- The part number is a random string and doesn’t help users to quickly see which type of part is being referred to

- A single part may end up with two or more numbers. One person might not be able to find the part number and simply assign a new number to the same item

- Identical parts from different suppliers might get different numbers even though they’re identical

- It’s difficult to look up alternatives or substitutes for a part, since the parts list has no order or logic

Duro empowers engineers to get to production at the lowest cost and highest efficiency. It helps you streamline part numbering and follow best practices. See how Duro can help your team by scheduling a demo.

How to implement part numbering best practices

Fortunately, hardware manufacturers don’t need to create their own part number format or product numbering system when they integrate their CAD tool with Duro. Duro PLM includes a category-based numbering scheme that allows engineers to search for the parts they need, choose acceptable alternatives, and communicate seamlessly with the operations department.

From the buying and operations sides, part numbering conventions consolidate the same parts from different hardware designs and make it easy for engineers to see if there are different approved sources and vendors who can supply the parts. A part numbering system makes hand-offs from CAD to the ERP systems seamless, providing a clear communication channel and eliminating misunderstanding or mislabeling of parts.

The overarching accomplishment of a numbering scheme is to avoid duplication. Part numbering best practices include:

- Consistent part number length

- Category-based part numbering

- Easily searchable categories

- Appropriate use of numbers and letters

- Flexibility for additions and changes in parts and assemblies

- Integration with all systems across the company

- Consistent number formatting for at-a-glance understanding of the part categories

- Ability to indicate acceptable substitute parts

- Single part number for identical parts from multiple vendors

Benefits of a Part Numbering System

Having an intelligent category-based part numbering system for electronics and hardware:

- Reduces time for engineers when searching for parts in their CAD system

- Eliminates duplication of part numbers

- Provides a unified part number, even when the same part can be ordered from different manufacturers

- Coordinates part numbers across the different internal computer systems using PLM

- Manages both individual parts and assemblies with unique part numbers

- Eliminates friction in communicating between departments

- Saves time and money in ordering the precise parts in the correct amount

- Eliminates copying and pasting of information from one system to another

- Frees up engineer and staff time to do higher-value work

PLM-based Part Numbering System

The PLM tool is the natural place to centralize the part numbers, because of the role that cloud-native PLM takes in the management of hardware products. Downstream systems such as purchasing, warehousing, and manufacturing benefit from having all the parts managed within the PLM.

However, sometimes the company already has a part numbering system that they prefer to use. Duro can integrate with existing part numbering schemes. It can take slightly longer to implement but Duro allows for flexibility based on client requirements The Duro system acknowledges the client’s system as the Primary Source for part numbers.

An integrated CAD and PLM system ensures cohesion

Some CAD systems maintain their own part numbering schemes. When integrating Duro, the designer can see both part numbers side by side. In the field, most teams will end up using the Duro part numbering scheme, simply because it’s more comprehensive, flexible, and searchable.

Duro helps companies accelerate their time to market with an intelligent part numbering scheme that smooths communications, reduces errors, and increases agile hardware production capabilities.