Guide To PLM-Based Engineering Change Orders and Release Management For Hardware Companies

Following on from our Simple Guide To Revision Management For Hardware Companies, we’re sharing our guidance on how to approach PLM-based release management, engineering change orders and release workflows

Hardware teams have a number of options when it comes to implementing an engineering release change order and approval workflow. No matter what option a company employs, any adopted workflow will be influenced by one truth about hardware development companies – the team that designs a product is not the same team that manufacturers it. Organizations that develop hardware will benefit from designing their engineering change order and release management workflow to account for this inevitable separation of responsibilities. While a single-phase engineering workflow management design will suffice in most cases, a two-phase engineering change order and release management workflow may better insulate engineers from excess administrative tasks, reduce the time required for change approval processing and promote the general agilization of hardware product development.

Find out how Duro’s award-winning cloud-native Product Lifecycle Management platform can improve your change order process by scheduling a demo.

The Two-Phase Engineering Change Order and Release Workflow

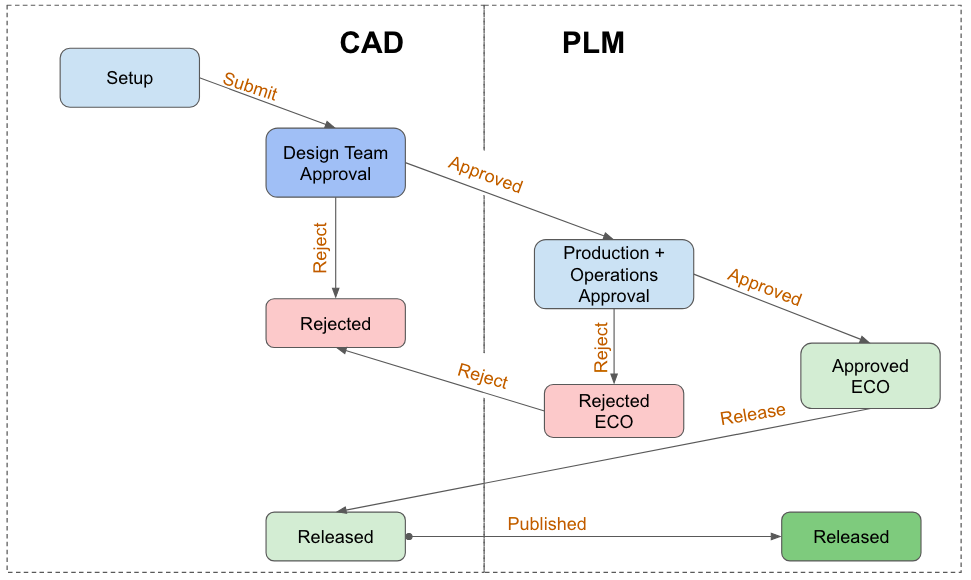

The following two-phase hardware release workflow delivers made-to-fit processes optimized specifically for hardware design teams and hardware manufacturing teams.

Phase-1

The first phase should be focused on how the change or release impacts product design or function, possibly involving no more than a design engineer and an engineering manager. A manufacturer or fabricator (like a machinist) can certainly be brought into this approval phase – to quickly assess potential manufacturing roadblocks – but the responsibility of approving the change is on the design team. In many cases the first phase can take place within a CAD tool, assuming the CAD tool contains a release management feature (e.g. Onshape, SolidWorks PDM, etc.). Otherwise, innovative engineering technology like a PLM engineering tool will certainly provide the necessary feature set.

Phase-2

The second phase should be focused on how the change impacts production, manufacturing, and the business in general. The stakeholders involved in the second phase will be more diverse than the first phase and departmental representation may vary by organization. The second phase diverges from the first phase in two key ways. First, the change is assessed for its impact on manufacturing schedule and cost rather than design. Second, a rejection of the change doesn’t necessarily send the change approval process back to the beginning, requiring re-approval from the design team. Approval requests can be recirculated within the stakeholders involved in the second phase if the reason for a rejection does not impact product design. Ideally, this second phase will take place within a PLM engineering tool which a wider audience can access.

With the fastest onboarding time and out-of-the-box third-party integrations, Duro empowers engineers to get to production at the lowest cost and highest efficiency.

Schedule a demo to see how easy it is to implement a two-phase release and approval workflow with Duro.

Figure 1: Two Phase Engineering Change Order and Release Workflow

Reducing the time required to approve a change

Hardware companies should be using innovative engineering solutions and working to reduce the time required to process any changes. Change management is never the core competency of a hardware product company and so it shouldn’t represent an ever expanding time commitment for the company. A two-phase engineering change order and release management workflow can help reduce the time required for change approval processing by decreasing the number of approval participants within each phase and by focusing each phase on the specific impact the change will impart to the organization. This leads to increased overall efficiencies via a more streamlined, fit-for-purpose process. Integrating your PLM with an ERP tool, like NetSuite, can also help reduce time for sharing information about changes and procuring the relevant components.

Insulate Your Engineers from Excessive Administrative Tasks

In an ideal world, engineers would not be slowed down by process. Engineers provide the most value by designing and building amazing products, not doing tedious administrative work. By reducing the amount of administrative work required from engineers, they can remain laser focused on creating value for the customer. A two-phase engineering change approval process allows companies to keep their engineers focused on their core job.

Keep the iterative nature of design development flowing

Two-phased release workflows encourage design development flow when compared to single–phase workflows. In most cases, single-phase workflows gravitate towards larger committees of reviewers, which stagnates progress. With an increased number of required reviewers and approvals, Change Orders can get “stuck” in the workflow. This is counter productive as it slows down progress and eliminates a core principle of agile development – iterate often and iterate fast. The smaller-sized review teams introduced through two-phase workflows facilitate faster approval processes and support a more iterative design process throughout all phases of product development and manufacturing.