Successfully navigating the hardware development lifecycle

A lot can go wrong when developing a hardware product. For example, supply chain issues might mean a launch delay, customers might not want the product you build, or you might fail to meet the necessary product regulatory and quality standards.

Avoiding these pitfalls and hitting your product objectives will require a well-planned and managed development process. Below is a guide to successful hardware development, focusing on a specific solution that can help you compress timescales and avoid mistakes.

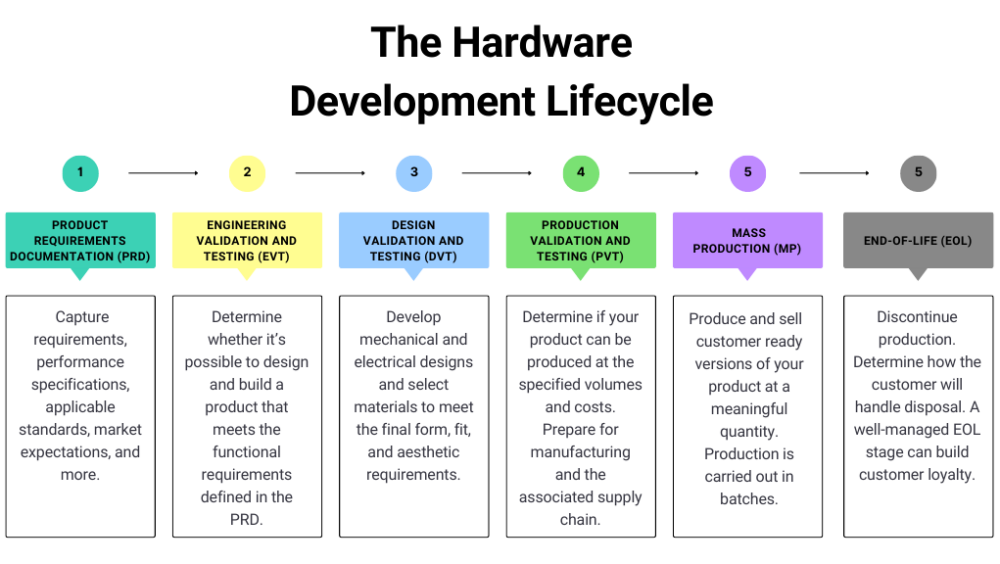

The 6 stages of any hardware product lifecycle

When creating a new product, focusing on functionality and appearance is tempting. Of course, appearance is important, but it’s not the only aspect to consider. Following a formal product development methodology helps ensure that you address everything, from standards and manufacturing process feasibility to end-of-life protocols.

A closer look at hardware product development methodologies reveals a pattern. The key stages that hardware development process gurus agree on are:

- Product requirements documentation (PRD)

- Engineering validation and testing (EVT)

- Design validation and testing (DVT)

- Production validation and testing (PVT)

- Mass production (MP)

- End-of-life (EOL)

Notice that while there’s a logical flow, these stages don’t always occur sequentially. Sometimes it may be necessary to loop around and repeat steps, and if you follow an agile hardware development process (similar to that used in software development), they may overlap.

1. Product requirements documentation (PRD)

The first step in hardware product development is to define what’s needed, which happens in the product requirements document (PRD).

The PRD captures requirements, performance specifications, applicable standards, market expectations, and more, putting them in one place for the design, development, testing, and manufacturing teams to access. Without these specifications, there’s a risk of spending time on unimportant design features while neglecting critical aspects.

A PRD template helps you get started; access Duro’s free PRD template here. Alternatively, you can use product lifecycle management software to document your requirements.

A PRD can include:

- Complete list of product features

- Specific performance metrics each feature must meet

- Estimated production volumes

- Target costs

- Target product release timelines

- Product roadmap

The Product Manager leads PRD creation but should solicit input and get final sign-off from Engineering, Sales, QA, and Marketing leaders, plus the Executive Leadership team. Once the PRD is approved, all subsequent product decisions must conform to what it says.

You might revise your PRD as new information that impacts earlier decisions is available, but each revision must go through the same review and approval process as before.

2. Engineering validation and testing (EVT)

The primary goal of EVT, sometimes referred to as prototyping, is to determine whether it’s possible to design and build an instance of the product that meets the functional requirements defined in the PRD. EVT entails identifying and resolving the technical challenges posed by creating physical prototypes.

The components selected and assembly processes employed at this stage can differ from what you’ll use in the final product. For example, duct tape and hot glue are acceptable, provided they allow you to construct something that functions and meets your specification metrics.

Getting to this point often takes multiple iterations, and it’s not uncommon to discover that some aspects are impossible to achieve. When this happens, the next step is to revise the PRD, after which EVT can resume. An important principle is that the product doesn’t leave the EVT stage until all the functional requirements and performance metrics are satisfied.

3. Design validation and testing (DVT)

Having established how to meet functional requirements, this next stage is where detailed product design occurs. Your team develops mechanical designs and selects materials to meet the final form, fit, and aesthetic requirements outlined in the PRD.

As with EVT, this is usually an iterative process. The materials and components selected in these revisions are candidates for the final production version, but you may choose alternatives later.

This is a good time to solicit customer feedback and begin testing product-market fit. Doing this early reduces the risk of wasting money on materials, tools, and processes required to start manufacturing.

A product leaves the DVT stage once it meets all functional and aesthetic requirements in the PRD while using candidate designs and components for final production. This version may be very close to, and visually indistinguishable from, the final version but possibly manufactured and assembled with lower volume processes.

4. Production validation and testing (PVT)

PVT aims to determine if your product can be produced at the volumes — and target costs — listed in the PRD. This stage may involve minor design changes or component substitutions, but the emphasis is on preparing manufacturing and the associated supply chain.

You can reduce estimated production costs by employing Design for Manufacturing, Design for Assembly, and Design for Testing methodologies — collectively called DFX. These require team approaches, often involving Purchasing, suppliers, and in-house manufacturing specialists.

In most cases, the identified changes are small and have an outsized cost impact. Some examples are:

- Replacing a part with a cheaper pin-compatible version

- Changing a draft angle so a molded piece ejects more reliably from the injection-molding tool

The PVT stage usually sees a shift from theoretical planning to actual manufacturing. A pre-production run helps surface any problems in the production processes and supply chain so you can address them before volume production begins. (A side benefit is that this provides the sales organization with samples to show customers.)

PVT is complete when product performance and quality meet the standards in the PRD, and you’ve established the supply chain. You’re ready to order parts at acceptable lead times and pricing, and the assembly and test procedures are repeatable and reliable.

5. Mass production (MP)

When a hardware product reaches mass production, you’re producing and selling customer ready versions of your product at some meaningful quantity. Depending on the product and market, production is carried out in batches, with each batch typically increasing in volume.

The manufacturer is responsible for procurement, assembly, and testing at this stage in the engineering lifecycle management process. Design and development responsibilities haven’t gone away completely, however. So you’ll help ensure quality and yields stay high while reducing costs. This may include working with procurement teams to help your supply chain keep costs and lead times low and supporting your manufacturing team by looking for improvements.

6. End-of-life (EOL)

In the product development sense, EOL generally refers to the discontinuation of the production of a product. However, another aspect is how the consumer/customer will handle disposal, which is becoming increasingly important as pressure grows to adopt “circular economies.” This section will look at both these EOL activities.

No matter how well-engineered or successful your product is, at some point, the demand will dry up, or a new, improved version will replace it. (Successful businesses strive to obsolete their products before competitors do it for them.)

When the time comes to cease production, you’ll need to address the following issues:

- How will you notify customers, and how much notice will you give them?

- Is there a need to continue producing the product as a spare part?

- What arrangements should be made for inventory? Will there be one last run to build stocks?

- How will you dispose of the remaining raw materials inventory, tooling, and unneeded production machinery?

A well-managed EOL stage can build customer loyalty and satisfaction by helping them upgrade to newer and improved products. But, handle it poorly, and there’s a real risk of them defecting to competitors.

Recycling is an increasingly important consideration regarding how the customer will dispose of the product when it reaches the end of its life. This may drive material selection and packaging design. Understanding requirements and customer expectations for recycling in each region where your product is sold is also essential.

Hardware development lifecycle challenges and solutions

By now, it should be clear there’s a lot more to successful hardware product development than simply working out how to incorporate a PCB into a housing. Instead, it would be best to consider every aspect of the product, from how you’ll make it to how you’ll dispose of it. The main challenges to address include:

Complexity

Modern hardware products often incorporate large quantities of physical components, plus fasteners, adhesives, and accessories like cables. In addition, the packaging can be nearly as complex, with instructions, warranty information, and appropriate protection and display features. This results in multiple bills of material (BOMs); typically, an engineering BOM for the hardware product, a manufacturing BOM, and a sales BOM.

The engineering BOM will often cover many interdependent systems and components that require careful design and testing. Unfortunately, defining, documenting, and keeping track of these components becomes a significant administrative burden without the right tools. (If you manage these activities carefully, the chances of the product being successful will stay high.)

The Duro solution:

Duro is a cloud-native product lifecycle management (PLM) platform. Cloud-based PLM simplifies PLM, and Duro helps manage complexity through:

- Streamlined and simplified processes

- Straight out-of-the-box functionality, avoiding the need for systems integrators

- Being intuitive for any team member to use means it doesn’t require an administrator to manage, and you can get up and running quickly

- Seamless integrations and transfer of data with your CAD, ERP and MES applications (which also supports effective collaboration)

Cost

Even if agile techniques compress the total project duration, numerous labor hours are almost always involved. There’s also the cost of tools and materials used during development, and possibly licensing and IP attorney fees.

A PLM tool helps keep costs under control in two ways. First, it helps avoid mistakes and wasted or duplicated effort because it provides a single source of truth for the PRD and associated documents. Second, it improves visibility into the process and individual activities, letting your managers prioritize and focus on areas where slippage might occur.

The Duro solution:

Duro supports cost-management efforts by simplifying and automating PLM activities. More specifically, with Duro, there’s:

- No need for a dedicated team member to manage the PLM system

- No need for system integrators to set up

- Faster ROI because team members can use it with minimal training

Time

Compressing product development lead time is one of the most significant factors in maximizing project ROI. The problem is that development and multiple validation cycles take time. One approach is to use agile development tools, which further complicates the challenge of maintaining oversight.

The solution is to use a PLM tool that performs the heavy lifting of coordination and tracking while providing visibility into product data and status.

The Duro solution:

Cloud-native Duro PLM helps meet this challenge with a few key attributes:

- Less time is needed to get the system running with no lengthy onboarding or integration and a streamlined product creation process

- Automated data entry, reducing manual input and accelerating data entry

- Ensuring data is accurate and readily transferred between design and manufacturing

Manufacturing constraints

Detailed drawings, specifications, and schematics are only valuable if you can manufacture the design. You might confirm manufacturability through various DFX analyses, but problems can still arise. For example, the manufacturing operation may need more capacity or a particular machine or tool. In addition, processes may take longer than expected, and there may be problems obtaining the required quantity or quality of components as needed.

The Duro solution:

Duro helps identify constraints and determine alternatives. Specifically, it:

- Facilitates collaboration with procurement

- Supports vendor selection (through its sourcing module)

- It avoids problems that could otherwise result from BOM errors

- Provides insight into availability and pricing at the time of design

Changing requirements (change management)

As new information becomes available during the project, you may need to update the design, BOM, and manufacturing processes. To minimize wasted time and money, you’ll incorporate these changes quickly and modify plans accordingly.

The Duro solution:

Duro was developed with change management in mind. It enables:

- Analysis and visualization of changes throughout each phase of design and development

- Visibility of component or product usage

- Traceability of changes and revisions

Regulatory compliance

In many industries, new products must satisfy a host of regulatory requirements. Leaving these until late in the project will likely result in rework and delays. So instead, your PLM solution should support compliance throughout the development process.

The Duro solution:

Duro helps manage documentation by making information readily available when needed and for audits when they occur. These two case studies help illustrate how Duro supports hardware development in highly regulated industries:

PLM software makes it easy

Everyone in software, firmware, or hardware development knows that bringing a new product to market is invariably challenging. The right PLM solution will make it easier.

A lot can go wrong, but Duro helps ensure everyone on the project can access the latest data. Duro PLM provides engineers with relevant information, including supply chain data, revisions and BOMs, so that they can do their jobs right the first time. It helps avoid mistakes and duplicated or wasted effort, which keeps the timeline on track, too.

The best way to discover how Duro helps bring products to market in less time is by seeing for yourself: Request a demo today.